Lead

Roel Baets – IMEC

Technical Coordination Team (TCT)

Technology description

The silicon photonics technology platform enables prototyping of complex, highly integrated photonic circuits in wafer scale silicon-on-insulator (SOI) technologies. The technology platform now available includes devices such as:

- waveguides,

- fibre couplers (horizontal and vertical),

- splitters,

- spectral filters,

- high-speed modulators,

- high-speed detectors

- and tuning elements.

The integration of these technologies on a single platform enables the design of sub-systems for high-speed communications (above 50 Gb/s), as well as for rapidly growing applications in:

- the sensing,

- life science

- and medical diagnostic sectors.

The technology will be made accessible through Multi-Project-Wafer (MPW) services as offered by Europractice IC-service and CMP in Grenoble. These process flows support high scale integration in 220nm or 310 nm SOI and are run in 200mm wafer CMOS fabrication lines, with 24/7 operation and statistical process control on the tools and processes. Europractice IC-service offers 4 silicon photonics MPW-runs every year and CMP offers 2 MPW runs, hence 6 total. This should accommodate the needs of most users.

On top of this four special silicon photonics technology offerings will be made accessible in TP5: VTT offers a 150mm wafer platform for passive photonic circuitry with micron-scale SOI waveguides and supports easier packaging and better polarisation independence, at a somewhat lower integration density. ORC, through the CORNERSTONE facility offers a Si-photonics platform based on 200mm wafer scale deep UV stepper/scanner technology with a higher process flexibility and faster turn-around time than is achievable in the MPW-offerings of the Europractice IC-service.

Finally, CNIT and UPV will provide fast prototyping and high flexibility in affording designs and fabrications on different silicon based platforms beyond available optical lithography using advanced electron beam facilities, on 150mm wafers. To increase the addressable application domain, Imec will in ACTPHAST4R also offer integration with novel materials, including graphene, III-V semiconductors (through die-to-wafer bonding or transfer printing) and ferroelectrics (LN, PZT).

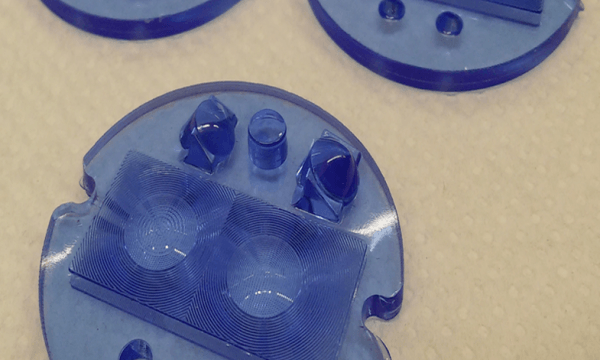

Packaging capability is crucial in this context since many researchers, certainly those from non-photonics background, have no expertise in handling unpackaged chips. The packaging capabilities provided within ACTPHAST4R (amongst others at Tyndall-UCC as well as Inphotec) complement those on offer through the PIXAPP Pilot Line, enabling the early stage packaged prototypes demonstrated in ACTPHAST4R to be transferred for scale-up to the Pilot Line.

Application domains

The silicon photonics platform can address a wide range of applications and markets in the wavelength range of 1.1 to 4 micrometers. These applications include:

- transceiver solutions covering the whole range from short-distance interconnect to long distance telecom;

- refractive index based biosensing applications,

- fingerprint vibrational spectroscopy through absorption spectroscopy or Raman spectroscopy,

- beam steering and LIDAR,

- laser Doppler vibrometry,

- OCT,

- microwave photonics,

- quantum optics and many others.

For operation outside the range of 1.1-4 micrometers silicon photonics can offer alternative CMOS-compatible solutions. For short wavelengths the silicon core can be replaced by amorphous silicon nitride. Solutions based on this approach are offered through TP7. For wavelengths longer than 4 µm custom solutions can be offered based on for example suspended silicon waveguides or Ge-on-Si waveguides.

Contact us to support your innovation project

If you have already a concrete project in mind you would like to discuss with ACTPHAST, register your intrest as a researcher or a company.

Submit your application as a researcher

Submit your application as a company

Do you have an open question?